Let Loose the Potential of Your Procedures With Proven Cane Sugar Processing Chemical Formulations

In the realm of cane sugar handling, the pursuit for functional quality is a continuous quest - Cane Sugar Processing Chemicals. The usage of tested chemical formulations has become an important aspect in enhancing production processes and boosting total performance. By integrating these formulations into your procedures, a range of benefits awaits, guaranteeing enhanced returns, increased purity levels, and structured processes that align with your strategic purposes. As the sector progresses, staying abreast of these advancements could be the setting apart variable that drives your operations to brand-new heights of success.

Enhancing Production Effectiveness

To maximize production effectiveness in walking stick sugar handling, it is essential to improve functional procedures and take on innovative modern technologies where relevant. By implementing efficient operational treatments, such as automating hands-on jobs and using data-driven understandings, sugar handling plants can dramatically boost their performance degrees.

In addition, incorporating state-of-the-art technologies like expert system and artificial intelligence can further revolutionize the cane sugar processing sector. These modern technologies can examine substantial quantities of information to enhance process parameters, predict tools upkeep requires, and enhance overall plant efficiency. By welcoming automation and digitalization, sugar handling facilities can operate with greater accuracy and reliability, ultimately leading to increased manufacturing outcome and enhanced product top quality. Fundamentally, the quest of production performance via streamlined processes and cutting-edge innovations is critical for the lasting development and competitiveness of walking cane sugar processing operations.

Taking Full Advantage Of Returns and Purity

Effectively making the most of yields and keeping high pureness degrees are essential objectives in the walking stick sugar handling industry. Achieving optimum yields while maintaining rigid pureness standards needs a tactical method that integrates sophisticated chemical formulations into the handling operations. By utilizing specific chemicals made to enhance removal performance, clarify the juice, and boost formation procedures, sugar mills can significantly improve their general yields and pureness levels.

Improving Refine Optimization

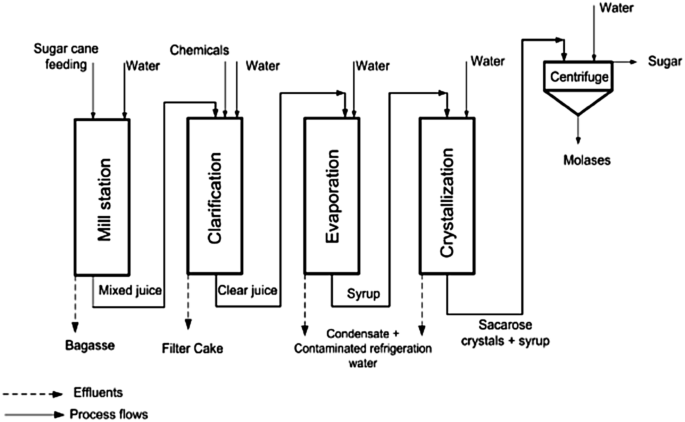

In the world of walking cane sugar handling, boosting procedure optimization is extremely important for achieving the desired yields and purity degrees while incorporating innovative chemical solutions for enhanced performance. Refine optimization entails fine-tuning numerous phases of sugar production to make best use of result while keeping top quality. One vital facet of boosting procedure optimization is the mindful calibration of tools such as evaporators, crystallizers, and centrifuges to guarantee they operate at peak efficiency levels. In addition, applying automation and surveillance systems can assist determine bottlenecks or inefficiencies in real-time, permitting for punctual modifications to improve total performance. Normal upkeep schedules and extensive cleaning treatments likewise play a critical function in maintaining the handling plant running smoothly and preventing unforeseen downtime. By continuously evaluating and maximizing each step of the sugar manufacturing procedure, operators can simplify operations, reduce power consumption, decrease waste, and eventually boost productivity. Accepting process optimization as a core concept can result in lasting enhancements in productivity and item quality within the walking stick sugar processing market.

Achieving Operational Goals Properly

With a strategic concentrate on functional quality, the sugar handling industry aims to successfully fulfill its production targets and quality requirements. Attaining functional objectives effectively needs a mix of variables such as streamlined processes, progressed innovations, and enhanced chemical formulations. By guaranteeing that each action of the sugar processing operation is meticulously intended and executed, business can improve efficiency and efficiency.

One trick facet of achieving functional objectives is the option of top quality cane sugar processing chemical formulations. These formulations play a critical role in various phases of the manufacturing procedure, consisting of extraction, purification, and crystallization. By utilizing proven chemical formulations specifically made for walking cane sugar handling, business can boost return, minimize processing time, and enhance the total top quality of the end product.

Moreover, reliable interaction and partnership among various divisions within the organization are important for aligning functional objectives and guaranteeing smooth workflow - Cane Sugar Processing Chemicals. Normal efficiency assessments, continuous training programs, and data-driven decision-making procedures can even more support the accomplishment of operational quality in the sugar processing sector. By carrying out these techniques, companies can read more unleash the complete capacity of their operations and stay in advance in a competitive market

Enhancing Output Quality

In addition, enhancing final result top quality likewise needs continual monitoring and modification of handling criteria to maintain consistency and satisfy top quality requirements. Quality control next page steps such as normal screening for purity, moisture material, and granulation make certain that the end product satisfies sector criteria and customer expectations. see this site By buying the ideal chemical solutions and focusing on quality throughout the production process, sugar processing facilities can accomplish remarkable final product top quality that establishes them apart on the market.

Verdict

To conclude, using tested walking stick sugar handling chemical solutions can substantially improve manufacturing performance, make best use of returns and pureness, improve procedure optimization, achieve functional objectives efficiently, and improve output high quality (Cane Sugar Processing Chemicals). By incorporating these formulations into procedures, companies can unlock the complete capacity of their sugar processing facilities and ensure a more structured and effective manufacturing procedure